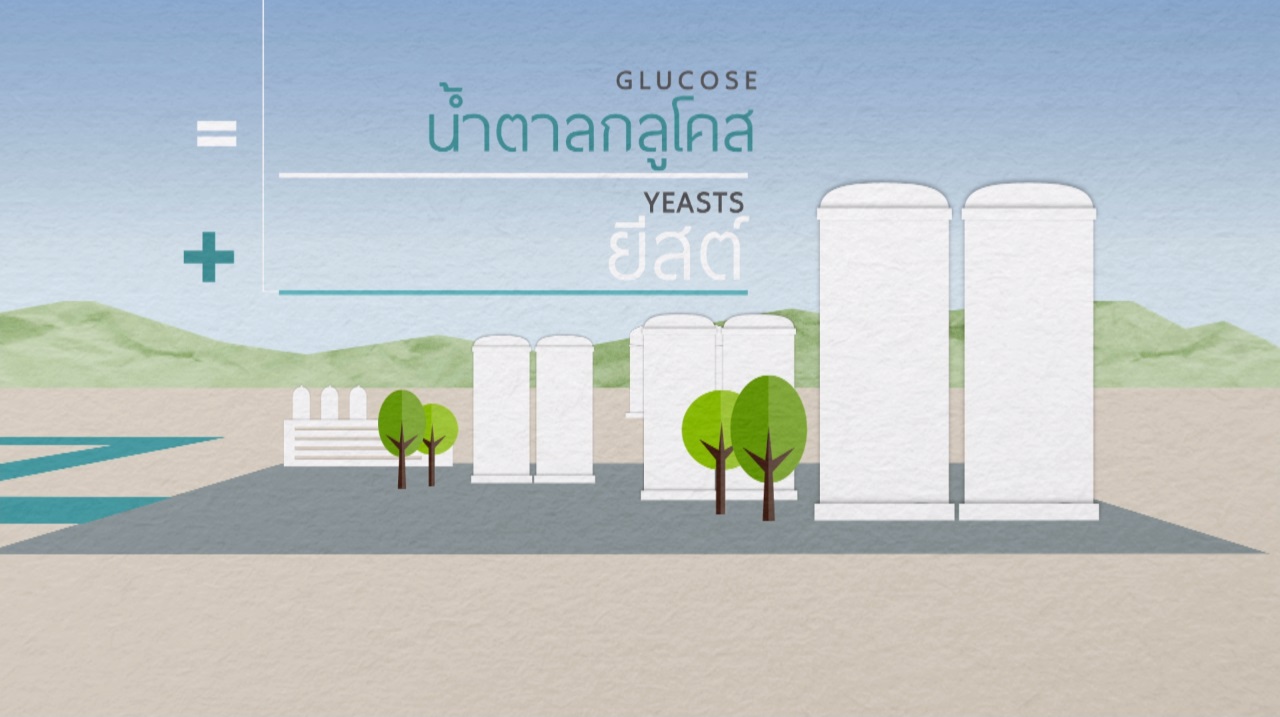

Ethanol, or ethyl alcohol, is produced by the fermentation of plants that turns flour into sugar, and then ferment sugar by using yeasts and enzymes. Afterwards, it is distilled into pure alcohol.

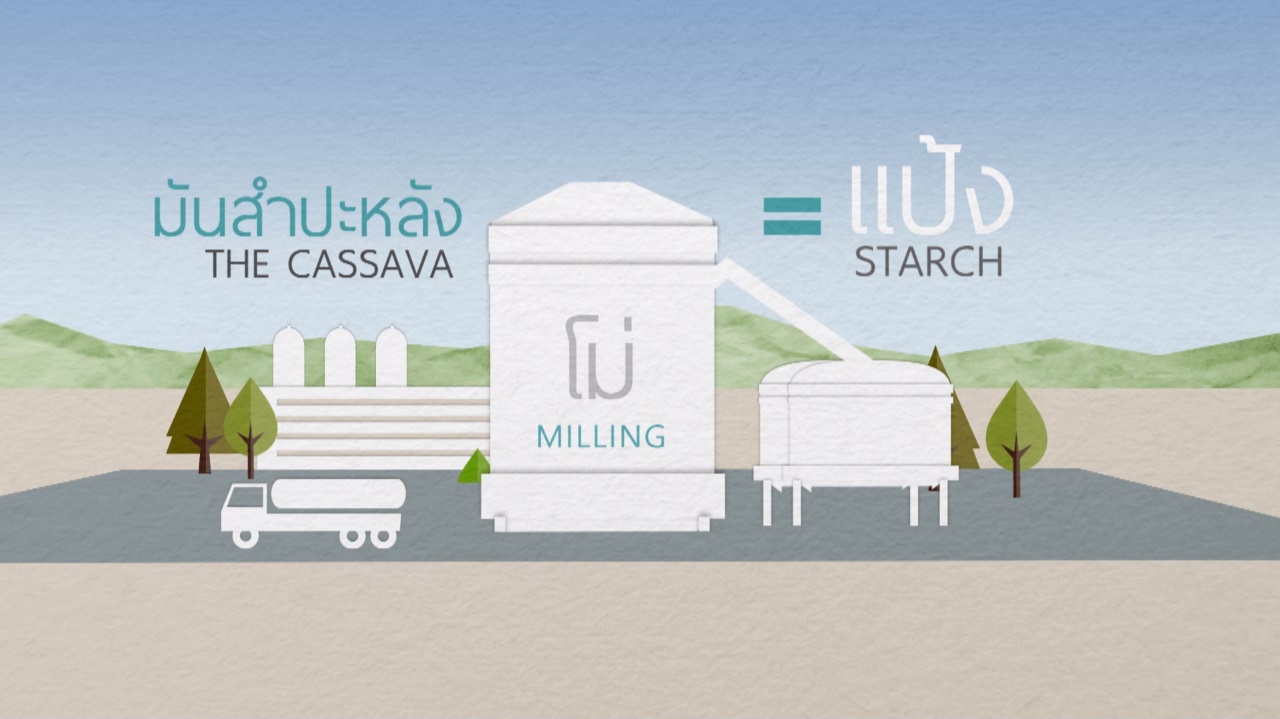

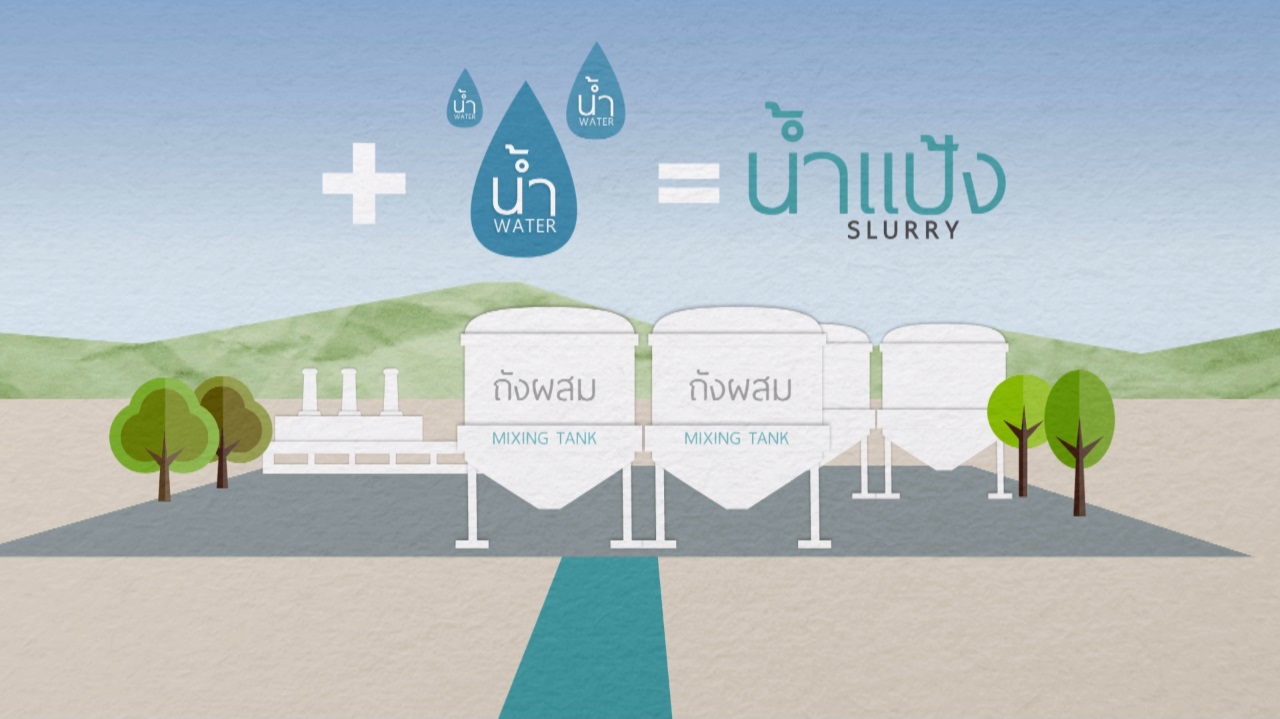

Sapthip’s ethanol production begins with preparation of ingredients, grinding cassava and mixed it with water in the barrel to turn in into flour. The flour will be added with alpha amylase enzyme to start the fermentation. The dextrin sugar will change into glucose. Thence, the yeasts will be added. Then the flour will be kept in barrels to produce 10-12% alcohol.

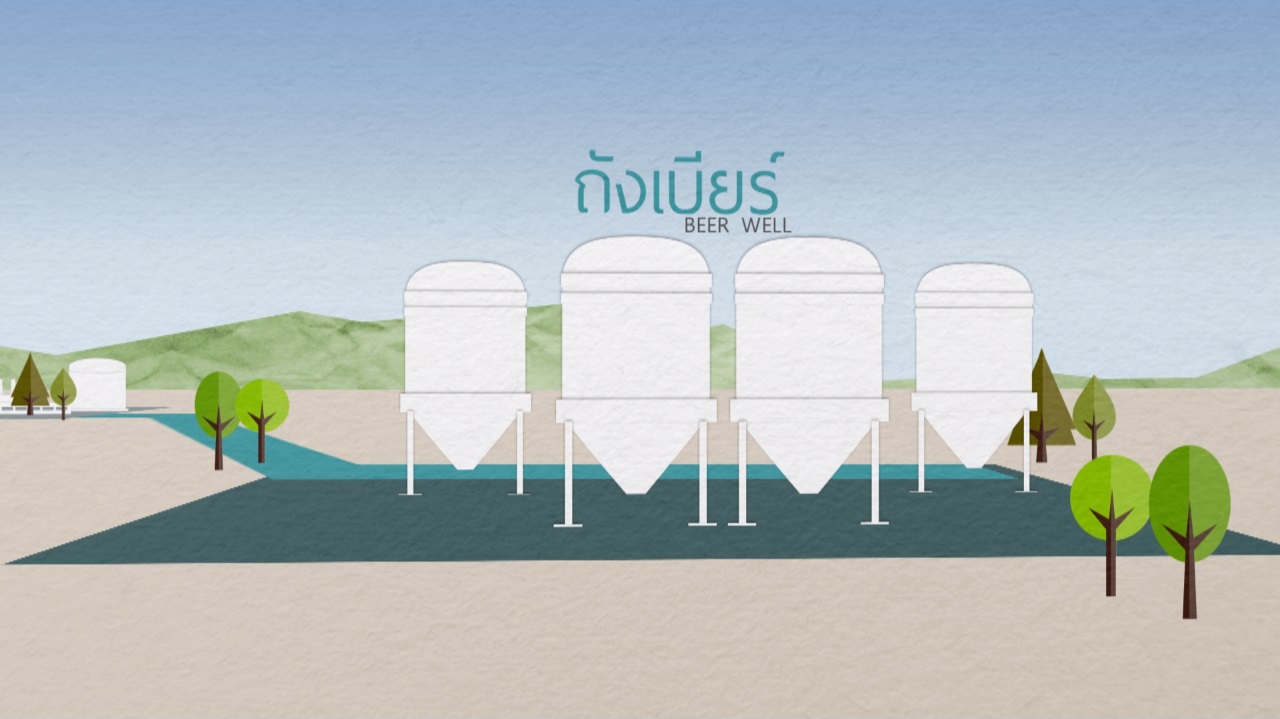

The fermented water will be filled in beer barrels for the distillation, to purify the alcohol. And then the distilled water will be dehydrated to separate 99.5% pure ethanol for mixing in fuel.

Every stage of production is certified with qualification standards in the hi-tech chemical laboratory.

- Production capacity is 200,000 liters per day

- Production capacity will be increased to 500,000 liters per day